Construction Methods for Athletic Apparel Part Two: Dye Sublimation

Posted by DANTE OTERO

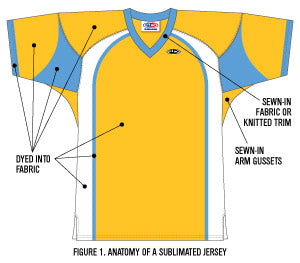

Custom dye sublimated garments are still sewn together from basic components such as the front and back body panels, sleeves and shoulders but the design detail is all dyed into the fabric as opposed to each color block, stripe or other element being a separate sewn-in piece of fabric.

I n figure 1 see an example of the same jersey design we used in the cut-and-sew discussion but made as a sublimated jersey. Notice that there are no seams around the areas of color in the sleeves, white side panel and blue trim. All of the different areas of color are dyed into the fabric. In the case of any areas of white in the design such as the side panels in our example, that is actually the lack of any dye present. All dye sublimated garments start out as white fabric so any color in the garment is dyed in. You can only sublimate white fabric. If you tried to apply sublimation to an already colored fabric the dye would not show up because it is a translucent dye and the colored fabric would show through.

n figure 1 see an example of the same jersey design we used in the cut-and-sew discussion but made as a sublimated jersey. Notice that there are no seams around the areas of color in the sleeves, white side panel and blue trim. All of the different areas of color are dyed into the fabric. In the case of any areas of white in the design such as the side panels in our example, that is actually the lack of any dye present. All dye sublimated garments start out as white fabric so any color in the garment is dyed in. You can only sublimate white fabric. If you tried to apply sublimation to an already colored fabric the dye would not show up because it is a translucent dye and the colored fabric would show through.

This opens up a vast array of unique design options that are not available with cut-and-sew garments. You can create designs with very thin and pointed areas of color that are not possible with the cut-and-sew process. With cut-and-sew, your design is limited by what can be handled and sewn together. For example the hockey jersey design in Figure 2 could never be reproduced with the cut-and-sew process because the areas of color in the design are too thin and too curved to be able to be sewn into the garment without bunching and distorting.

This opens up a vast array of unique design options that are not available with cut-and-sew garments. You can create designs with very thin and pointed areas of color that are not possible with the cut-and-sew process. With cut-and-sew, your design is limited by what can be handled and sewn together. For example the hockey jersey design in Figure 2 could never be reproduced with the cut-and-sew process because the areas of color in the design are too thin and too curved to be able to be sewn into the garment without bunching and distorting.

Another design technique that is unique to dye sublimation is the ability to use a pattern or ghosted "watermark" image as a background. This can be any pattern, image, logo or design that you want. You can also use a gradient in your design to make areas of the garment go from light to dark or dark to light, or from one color blending to another color. It also allows us to change the colors in camo patterns so you can use unique colors in the camo pattern itself that complement your team colors.

Another design technique that is unique to dye sublimation is the ability to use a pattern or ghosted "watermark" image as a background. This can be any pattern, image, logo or design that you want. You can also use a gradient in your design to make areas of the garment go from light to dark or dark to light, or from one color blending to another color. It also allows us to change the colors in camo patterns so you can use unique colors in the camo pattern itself that complement your team colors.

Also, all trim options such as piping, braiding and sleeve trim can be sublimated into the fabric as well so it will still look the same but without the additional labor cost of manually sewing the trim into the garment. In the figure 1 football jersey example, the blue trim that follows the white side panels and the blue trim on the ends of the sleeves were sewn into the garment with the cut-and-sew process but are dyed into the fabric in the sublimation process. We can still add sewn-in mesh inserts for ventilation or spandex side panels to sublimated jerseys but it will increase the cost.

Also, all trim options such as piping, braiding and sleeve trim can be sublimated into the fabric as well so it will still look the same but without the additional labor cost of manually sewing the trim into the garment. In the figure 1 football jersey example, the blue trim that follows the white side panels and the blue trim on the ends of the sleeves were sewn into the garment with the cut-and-sew process but are dyed into the fabric in the sublimation process. We can still add sewn-in mesh inserts for ventilation or spandex side panels to sublimated jerseys but it will increase the cost.

In addition to the actual design of the garment, all decoration for numbers, lettering, logos, player's names, etc. are dyed into the fabric at the same time the garment design is applied. This allows us to sell all custom sublimated apparel at a flat price regardless of the amount of decoration. The only exception is with AK apparel there is an additional cost for player's names, but for Dynamic and Prosphere sublimated apparel there is no extra cost.

In addition to the actual design of the garment, all decoration for numbers, lettering, logos, player's names, etc. are dyed into the fabric at the same time the garment design is applied. This allows us to sell all custom sublimated apparel at a flat price regardless of the amount of decoration. The only exception is with AK apparel there is an additional cost for player's names, but for Dynamic and Prosphere sublimated apparel there is no extra cost.

Another advantage of sublimated apparel there is no minimum required for fill-in orders. Since all of the set up has already been done on the initial order and it is an entirely digital process, all we have to do is print as many more transfer sheets as needed and apply them to pre-cut garment panels that we keep in stock and we can make just one garment if you need it.

You can read a detailed technical description of how the dye sublimation process works on our What is Dye Sublimation page.